|

|

|

|

|

|

SDK and Microwave Chemical will aim to develop a technology that decomposes used plastic containers and packaging by irradiating microwave, thereby producing basic chemical feedstock such as ethylene and propylene. By the end of this year, the two companies will study conditions for formation of product through microwave heating, search for catalysts to improve the yield of targeted components, and try to optimize conditions and processes for decomposition to establish basic technology.

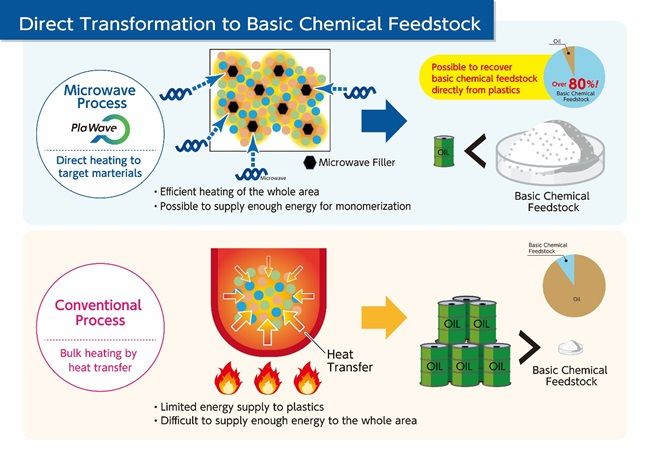

In the joint technology development, the two companies will use microwave heating, a kind of electric heating used also in a microwave oven. When an object is irradiated, microwave directly affects dielectric material, resulting in internal heating, selective heating and rapid rise in temperature. Compared with other heating methods, microwave heating is special in that it heats only the object. In the planned process, we will use microwave absorber (filler) to give energy in a focused way to used plastic, enabling efficient decomposition of used plastic into basic chemical feedstock. It will also reduce energy consumption for decomposition compared with conventional methods. (Chart 1) Taking advantage of such characteristics of microwave heating, we will aim to transform used plastic directly into basic chemical feedstock with low energy consumption and high efficiency.

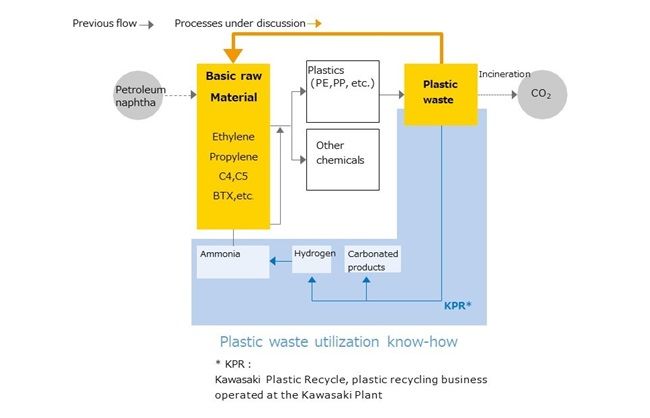

SDK has been engaged in chemical recycling operations since 2003 at its Kawasaki Plant, producing clean hydrogen and ammonia through thermal decomposition of used plastic. As a result, SDK has accumulated overall know-how concerning procurement of raw materials, decomposition, and manufacture of final product. (Chart 2) With its high-level technologies and deep expertise in process development, Microwave Chemical has the capability to scale up microwave technologies. In the area of chemical recycling, the company has established "PlaWave(TM)," a platform of microwave-based plastic decomposition technology, thereby dealing with various types of plastic.

SDK and Microwave Chemical will work together to contribute toward achieving resource saving, resource circulation and a carbon-neutral society through this joint development.

About Showa Denko K.K.

Showa Denko K.K. (SDK; TSE:4004, ADR:SHWDY) is a major manufacturer of chemical products serving from heavy industry to computers and electronics. The Petrochemicals Sector provides cracker products such as ethylene and propylene, the Chemicals Sector provides industrial, high-performance and high-purity gases and chemicals for semicon and other industries, the Inorganics Sector provides ceramic products, such as alumina, abrasives, refractory/graphite electrodes and fine carbon products. The Aluminum Sector provides aluminum materials and high-value-added fabricated aluminum, the Electronics Sector provides HD media, compound semiconductors such as ultra high bright LEDs, and rare earth magnetic alloys, and the Advanced Battery Materials Department (ABM) provides lithium-ion battery components. For more information, please visit www.sdk.co.jp/english/.

For further information, contact:

Showa Denko K.K.

Public Relations Group, Brand Communication Department

Phone: 81-3-5470-3235

Microwave Chemical Co., Ltd.

Public Relations (Okunaka)

Phone: 81-6-6170-7595

Email: pr@mwcc.jp

Copyright 2022 ACN Newswire. All rights reserved. www.acnnewswire.com

source https://www.acnnewswire.com/press-release/english/76120/